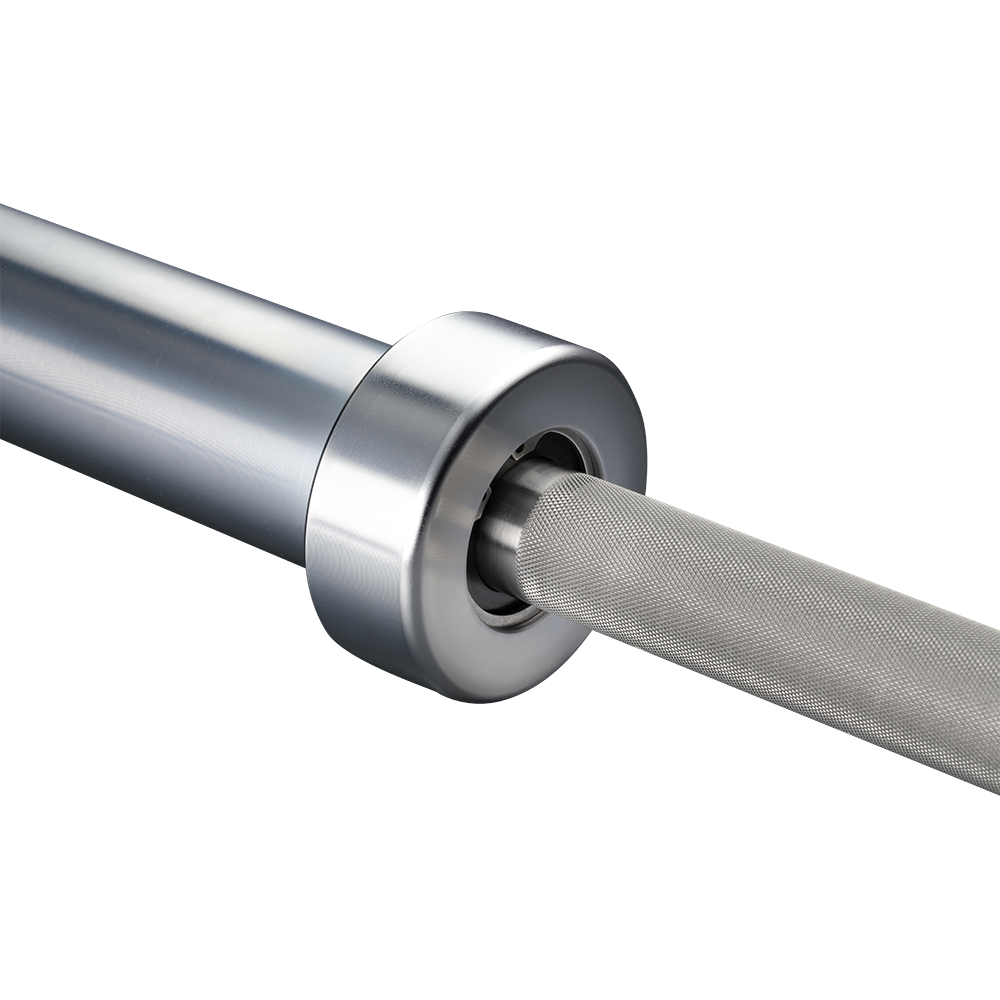

Many are confused as to what determines a great performing needle bearing bar, which is also known as a Competition style IWF Olympic Weightlifting Bar. First, it’s important to understand what exactly an optimum performance bar looks like. The goal is simple; the bar sleeve must spin-unrestricted with all loads and have a smooth feel with no play up and down on the bar shaft. Many buyers or users make the mistake of spinning an unloaded bar sleeve by hand and listening for that skateboard wheel sound (bearings touching the bar) as well as watching and counting how long it will remain spinning to "test" a bar. From a design and mechanical engineering standpoint, this is unrelated to the way a bearing bar will perform when loaded, and especially the heavily loaded condition. In fact, a bar that is not precision-made and built to have wide tolerances vs. super precision tolerances will, in fact, spin faster and longer (when unloaded) than a precision bearing bar.

What a precision bearing bar will do, however, is spin slower unloaded and effortlessly when fully loaded because then there is virtually no play between the Bar Shaft and the case-hardened needles inside the bearings (or the bearings and a race system). A bar/sleeve combination that continues to spin upon completion of the snatch, clean or jerk creates an unstable condition that can lead to a loss of balance or a change in bar trajectory during the jerk-drive phase. Additionally, in a correctly built bar, each bearing will be packed with a low-friction grease that protects the bar shaft and bearings over time, which slows down a spin test by hand. Precision bearings are meant to spin more than 15,000 RPM (revolutions per minute), and a lifter rotates the bar at half of 1 turn. If the precision bearing system were attached to a drive motor there would be zero sign of a slow-moving system. In fact, this precision bearing system would be much smoother and quieter than a system that you could hear. What American Barbell has done is take this entire process several steps further by addressing problems that have plagued the Olympic Bearing Bar from day one.

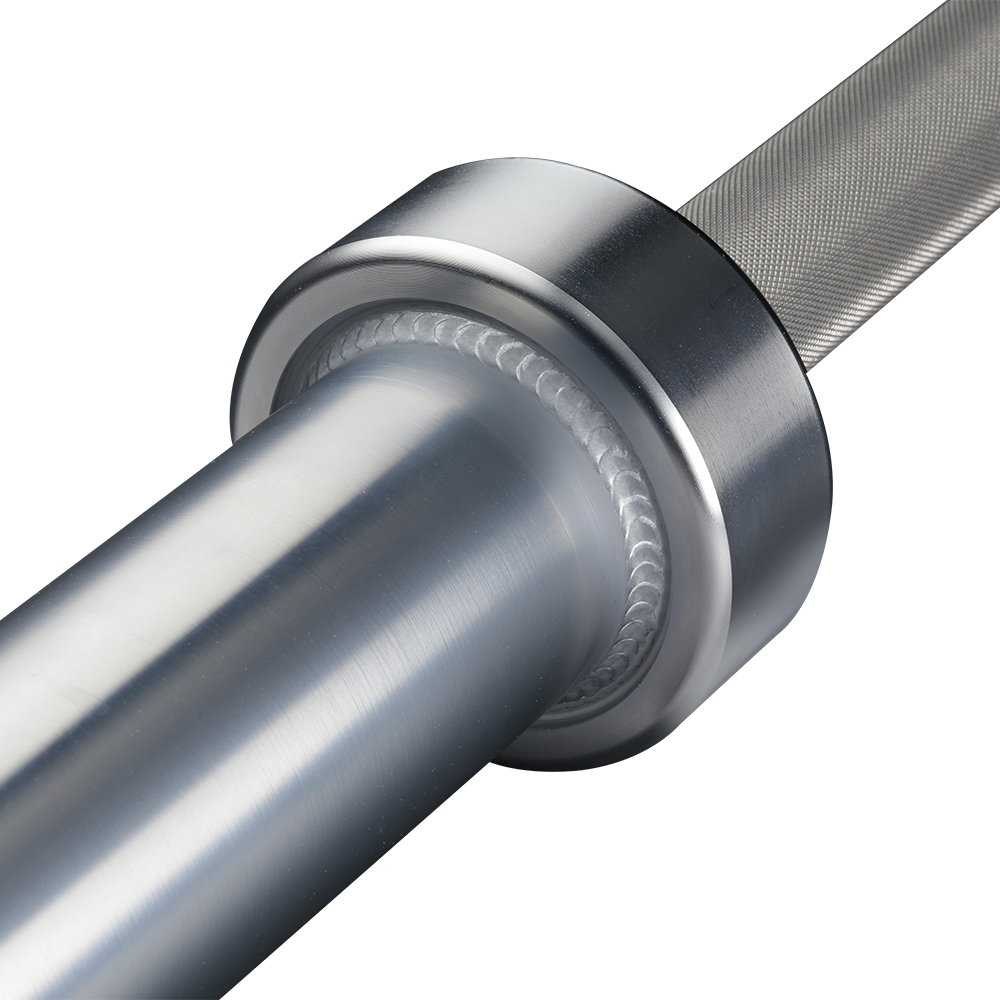

First, we use a super precision needle bearing that is substantially larger, stronger, and higher load rated than the rest. This bearing is more expensive than the conventional bearing found in most bars today and rotates around an inner race/sleeve that fits over the bar. With this method, needle bearings do not come in contact with the bar shaft, which is crucial for long life and continuous smooth rotation. Because needle bearings are much harder than ANY bar shaft material used in Olympic lifting, this system is far superior compared to bars that have the bearings directly rotating around the bar shaft. When these hard needles are directly on the bar shaft, they immediately begin to deform the bar from constant dropping. Conventional bearing systems create a similar effect; as if you took a hammer and repeatedly hit the side around the bar over and over again. Over time the bar shaft develops flat spots under the needle bearing areas that create a very rough and non-concentric rotation. At this point, the bar has been damaged beyond repair. From an engineering perspective, no bearing should come in direct contact with a mating surface that is SOFTER than the bearing itself, which is virtually impossible in almost all available finishes, especially decorative chrome.

In the American Barbell Bearing system, both the bearing and the race are not only protecting the bar but also allowing the use of many different types of materials. As mentioned in the example above, if a standard type Needle Bearing Bar with bearings was spinning at 15,000 RPM’s, the bearings would score the bar. This is due to the way the glass is cut, causing catastrophic failure. Therefore, we entirely prefer the bearing and race method. Many companies today still use conventional decorative chrome on the bar shaft, which is typically found on car bumpers. Using this finish is dangerous because it is not made to flex, as any good bar should. Once the chrome shell is broken, it peels, leaving areas sharp as a razor blade. At American Barbell, we would never use a finish of this type. We do, however, use a hard chrome aircraft finish in some applications where a particular hardness is required, as this method will NOT peel.

The reason more companies have not gone this way is because of the significantly higher cost required to produce these bars with precision machinery. The real bar test is to load a bar heavily and ensure that there is zero restriction and a solid feel, especially when dropping the bar. This technical information can easily be verified by any mechanical engineer or technical bearing expert. The looser the tolerances are, the faster the spin. The same holds true for bushing bars; a loose bushing will always turn faster but not rotationally smoother, as the bar will always find the flat spots of the bushings creating knocking. At American Barbell we don’t copy. We innovate.

In summation, when addressing how a sleeve spins on an Olympic Bar, consider the fact that it does not matter if the sleeve spins like a skateboard wheel when unloaded, as this does not correlate to the purpose of a rotating sleeve on an Olympic Bar. At American Barbell, we design equipment for their most efficient intended use. The most important function of a rotating sleeve is to be fast and smooth, under load, during a lift. Our race & bearing design fits this mindset beautifully, resulting in a needle bearing far that spins exceptionally well under load in an aggressive lifting environment. Our main concern is flawless product execution and surpassing the expectations of our customers. We love to discuss the Features, Advantages, and Benefits of our products, but don’t just take our word for it, read our customer reviews and testimonials from some of the top coaches in the weights industry. Here you will see how our products perform where the rubber hits the road.

Phil Patti

CEO - American Barbell